Texneo

Our commitment to the planet

At Texneo, caring for the planet is a design and process decision. We work to reduce impacts from yarn to finishing, prioritizing raw materials with recycled content or from renewable sources and evolving processes to consume less water, energy, and chemicals, always with proper effluent control.

Water Resources

Water is essential for the textile sector, which is why Texneo manages this resource throughout the entire journey. We start with conscious use, controlling consumption at each stage of the process, standardizing baths, and adjusting dosages to avoid waste.

All water used in production goes through treatment systems before being returned to the environment. In these systems, impurities are removed in physical, chemical, and biological stages, and the quality of the treated water is periodically monitored to meet environmental legislation.

Furthermore, we continuously seek improvements that reduce the need for water in processes, combining technology, preventive maintenance, and team training to ensure a more efficient and responsible cycle.

Through new technologies and a continuous process of monitoring and improvements, we achieved great advances in processes in 2024, optimizing consumption for each stage. At the same time, the retrofit of the dyeing machine allowed for the use of a smaller volume without compromising dyeing quality.

With this, it was possible to process more fabric using the same infrastructure and reducing the water need for each kilogram (kg) produced, despite the increase in the total volume of water captured due to production growth. These changes also positively impacted other indicators.

After use in industrial processes, the water goes to the WWTP (Wastewater Treatment Plant), where it passes through an Ozone treatment system, ensuring that discarded effluents are within required environmental standards.

Energy and emissions

At Texneo, we also look at energy use through the impact it generates on the environment. First, we map where our energy comes from (electricity and fuels) and how it is used at each stage of the productive process. With this, we can identify where it makes sense to reduce consumption and where it is necessary to invest in more efficient technologies.

We seek, whenever possible, to use electricity from certified renewable sources, which contributes to decreasing emissions associated with our operations. In parallel, we promote improvements in equipment, heating systems, and infrastructure to do more with less energy, maintaining color stability and fabric performance.

We also monitor greenhouse gas emissions related to energy use and other operational activities, which allows us to evaluate results, compare scenarios, and plan next steps toward an increasingly sustainable energy matrix.

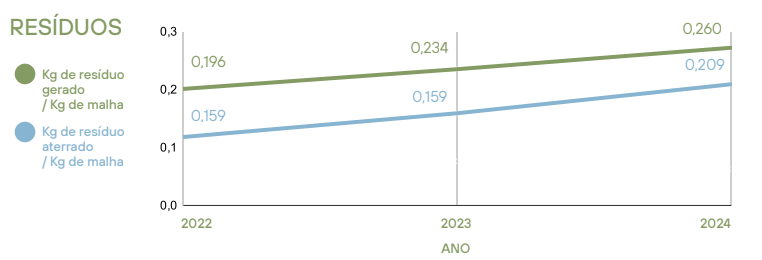

Waste and circularity

At Texneo, we work to minimize waste generation and give the best possible destination to each type of material. In production areas, for example, we separate by type (textiles, paper, plastic, metal, hazardous waste, among others) and direct each category to the appropriate path, prioritizing recycling and reuse whenever possible.

We rely on specialized partners for material recycling and packaging compensation programs, which helps reduce the impact generated throughout the chain. In cases where recycling is not viable, such as part of the sludge generated in effluent treatment, we ensure it is sent to licensed companies, following all environmental requirements.

At the same time, we work to generate less waste at the source, adjusting processes, reducing raw material losses, and stimulating the conscious use of inputs. Thus, we decrease the volume sent to landfills and strengthen a more responsible chain aligned with circularity principles.

The inauguration took place in the last quarter of 2024, reinforcing the commitment to improving these indicators for the coming years.

Transparency that guides our goals

Follow annual results with indicators, goals, and historical series, as well as cases and methodologies. Reports available in multiple languages for customers and partners.

Certified quality and responsibility

Great Place to Work

Eu Reciclo

Green Fiber

Recycled Blended

I-REC Standard